© Copyright 1976-2021 Shazhou Textile Dyeing Import & Export Co., Ltd. All rights reserved. Powered by iwonder.cn

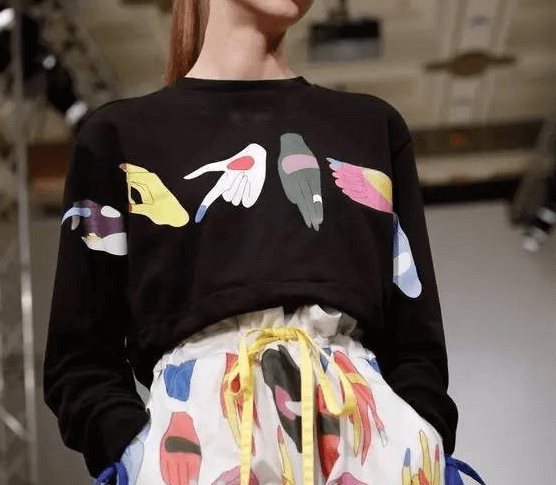

Fabric modification is a very good way of expression. Through dyeing and printing of fabrics , designers can better integrate personal styles into their works. A lot of designers will run out of inspiration, mostly because the design can't fall to the ground. Design does not appear out of thin air, whether it is creative thinking mode or rigorous design logic, it needs to be presented visually. The design of fabric is exactly the place where designers need to think and be creative when designing clothes.

Today, we are going to look at the very important and very common printing of fabrics.

1. According to material classification: water slurry printing, glue printing, semi-paste, ink printing, thermosetting ink printing, gold and silver powder, hot foil printing, foam printing, silicone printing, reflective printing, flocking, imitation dyeing Printing, flash printing;

2. According to the process classification: manual printing, transfer printing, letterpress printing, dial printing, dot printing, four-color printing;

3. Classified by printing methods: transfer printing, paint

Printing technology

1 Water serigraphy: Features: The color is relatively dull, but it is relatively soft and can be combined with the softness of the fabric.

2 Paste printing (Ger print also known as Rubberprint): glossy and matte, with soft, thin, environmentally friendly features, can be stretched. Suitable for fabrics: fabrics that do not absorb, such as coated fabrics.

3 Semi-Mastic: Features: Between the characteristics and the water slurry and glue between the two. It has better coverage than water paste and can be printed on dark fabrics. It also has better washability than water paste, but it is thinner than glue and will not have a hard texture. Generally on T-shirts. Used more often.

4 ink printing: Features: bright color, vivid image, hard. Suitable for fabrics: coated fabrics that do not absorb. A wave of people's headprints rose in the market some time ago. In general, a clear and ultra-realistic printing can only be printed in ink printing.

5 thermosetting ink printing: thermosetting ink English: PLASISOL, thermosetting ink, also known as plastic ink, or self-adhesive ink. Applicable to 100% cotton, cotton/polyester blended, polyester, light-colored cloth, denim and other fabrics, all fabrics that meet the following two points can be used: 1, can withstand 150 °C; 2, a breathable, can make Ink penetrates.

6 gold and silver powder printing: also known as gold printing and silver printing.

8 hot foil printing: also known as laser printing. Refers to the use of metal foil or pigment foil, by heat transfer to the surface of prints or other items, in order to enhance the decorative effect.

Shazhou Textile offers a wide range of production and processing experience to provide you with cotton, cotton, flannel, elastic cloth, polyester/cotton, printing, dyeing, CVC, T/C, and custom-made production and processing. Welcome your inquiry .